Ever wondered what those large, metal boxes used to transport goods across the globe are made of? You're not alone. Shipping containers, often seen stacked high on cargo ships or trains, are crafted from very specific materials for durability and longevity.

Primarily, shipping containers are made from steel. Known for its strength and resistance to harsh environmental conditions, steel is a go-to material in the manufacturing of these sturdy structures. The walls of shipping containers typically consist of corrugated weathering steel-a type known as Cor-ten-while the frame is constructed with stronger types of steel.

However, it's not all about metal when it comes to shipping container construction. They also incorporate other materials such as plywood or bamboo for flooring purposes. These materials offer a durable yet lightweight solution that complements the robustness of the steel structure while keeping weight down.

Compare Prices on Steel Shipping Containers

Understanding Shipping Containers: An Overview

Let's dive right into the world of shipping containers. These giant boxes have become a ubiquitous sight in our globalized world, transporting goods from one corner of the globe to another. But what exactly are these containers made of? You might be surprised to find out that they're more than just big metal boxes.

At their core, shipping containers are crafted from high-quality steel known as "Cor-ten steel. This is a type of weathering steel that's built to withstand harsh climate conditions and resist corrosion over time. It's essentially the superhero of steels when it comes to durability and strength.

But it isn't all about steel in these units. They also sport several other components like plywood or bamboo floors for stability and grip during transport. The doors, meanwhile, feature rubber seals to make them watertight and protect your precious cargo from moisture damage.

Did you know there's also a bit of chemistry involved in making shipping containers? That's right! To prevent rusting, manufacturers often apply zinc coating on the surface which serves as an additional protective layer against corrosive elements.

Now let's talk numbers:

| Material | Percentage |

| Steel | 90% |

| Wood | 5% |

| Rubber | 3% |

| Other | 2% |

As shown above, most of a container is indeed made up of steel but do notice how other materials play important roles too!

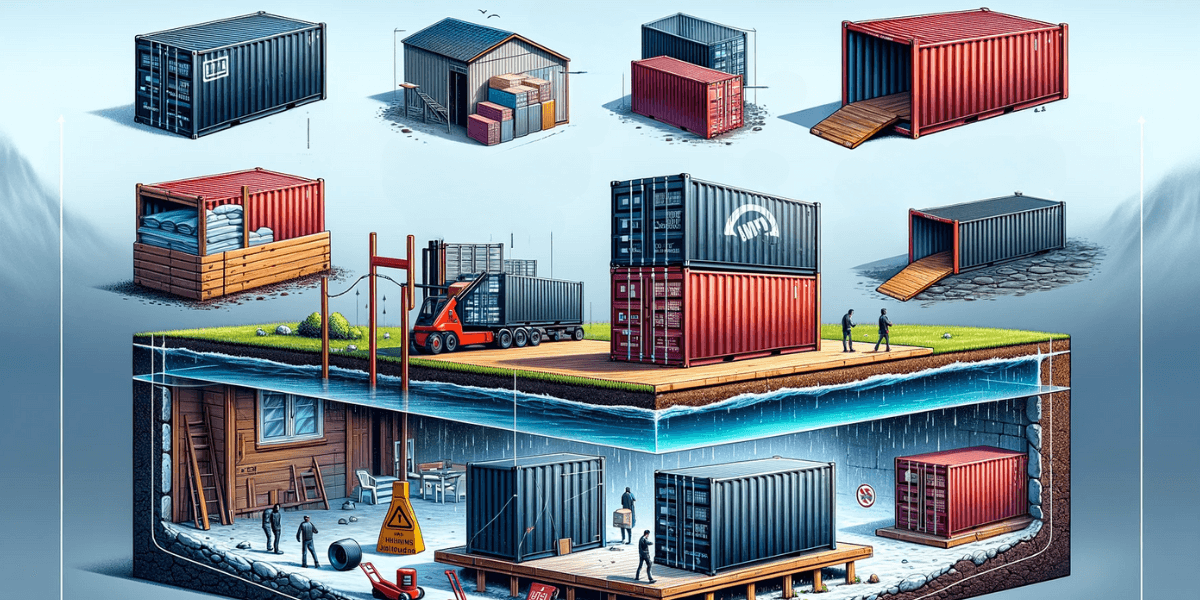

Of course, there are different types of shipping containers out there - refrigerated ones for perishables like fruits or medicines; open-top ones for oversized items; tank containers for liquids or gases...the list goes on! Each variant has its unique design considerations and material composition based on specific use cases.

In essence, we've barely scratched the surface here! There's so much more behind these versatile marvels - all playing a pivotal role in keeping our global economy ticking. We hope this glimpse into what shipping containers are made of has given you an appreciation for the complexity and thoughtfulness that goes into their design and creation.

Materials Used in Shipping Container Construction

We're diving right into the heart of what makes up these versatile structures. The main material used in shipping container construction is steel, a durable and robust metal perfect for long journeys by sea, rail, or road. It's an alloy composed primarily of iron combined with carbon to enhance its strength and hardness.

Beyond the primary component of steel, there are different types involved:

- Corten Steel: This 'weathering' steel forms a protective layer when it comes into contact with atmospheric conditions. It's this feature that gives shipping containers their iconic rust-like appearance yet prevents further corrosion.

- Stainless Steel: Certain sections of the container may use stainless steel due to its resistance against corrosion and staining.

Now let's look at some specific elements:

- Flooring Material: While the walls and frame are made from Corten Steel, most containers have wooden floors. Typically constructed from high-quality plywood or bamboo, they provide both durability and a somewhat softer surface for cargo.

- Paint: Containers aren't just bare metal; they're usually painted for added protection against weather elements. These paint coatings often contain chemicals like phosphoric acid to prevent rusting.

- Door Seals: To create water-tight doors on these containers, rubber seals are used around the edges ensuring everything inside stays dry regardless of external conditions.

So there you have it! That's essentially what goes into building these incredibly sturdy structures we know as shipping containers: predominantly Corten Steel but also other materials such as wood for flooring and rubber seals for watertightness each playing their crucial part in maintaining durability under extreme conditions.

Process of Manufacturing Shipping Containers

Shipping containers, those ubiquitous symbols of global commerce, are made from a surprisingly simple combination of materials. The majority of these hardy structures are created using Cor-Ten steel. This stuff is tough! It's also known as weathering steel due to its ability to withstand the elements. But let's take a step back and walk through the process from start to finish.

The manufacturing journey begins with large rolls of Cor-Ten steel. These rolls are uncoiled and cut into sheets that match the size specifications for individual container parts - sides, ends, doors and roofs. Precision is key here; after all, we're crafting a product designed to endure long sea voyages and heavy loads.

Next up in our process is pressing. Those freshly cut sheets? They're pressed into corrugated panels in massive molding machines that apply tons (literally!) of pressure. Ever notice how shipping containers have that signature wavy texture? That's down to this stage in the production line.

Now it's time for assembly - where we fit together all those different pieces like an industrial jigsaw puzzle. We'll join them using electric resistance welding techniques which ensure strong bonds between each section.

Before hitting the paint shop, every container goes through quality checks because no one wants their goods arriving less than perfect! After passing inspection, they're sandblasted clean then coated with marine grade paint - creating another barrier against wear and tear on their worldwide travels.

Finally, wooden floors made from apitong or keruing hardwoods are installed inside each unit providing durability underfoot while handling hefty cargoes - another testament to our commitment towards resilience and longevity in every manufactured shipping container.

So there you have it! A behind-the-scenes glimpse into how we transform sturdy steel sheets into the robust shipping containers crisscrossing our continents today.

The Durability and Lifespan of Shipping Containers

Let's dive right into the heart of what makes shipping containers so durable. They're principally made from high strength, corrosion-resistant Corten steel. This material is designed to withstand harsh weather conditions and heavy loads - it's truly built to last.

Durability isn't just about the materials used; it's also about design. Shipping containers have a unibody construction, meaning they're composed of one solid piece with no separate frame or body parts. We're talking a box that doesn't bend or break easily because its structural integrity remains intact even under immense pressure.

Now, how long can these rugged steel boxes last? Well, it depends on their usage and maintenance but generally speaking, a well-maintained shipping container can serve you for 25 years or more! That's impressive when compared to other types of storage structures.

Here are some quick numbers:

| Material | Expected Lifespan |

| Wood | 10-15 years |

| Plastic | 15-20 years |

| Steel (Shipping Container) | 25+ years |

We shouldn't overlook maintenance in this discussion though. Remember that corrosion is the number one enemy of any metallic structure - yes, including our sturdy Corten steel containers. Regular inspection and prompt repair at the first sign of rust will go a long way in extending their lifespan.

It's noteworthy too that repurposing shipping containers gives them an extended life beyond sea transport - think trendy coffee shops or comfy tiny homes! These novel uses aren't just eco-friendly; they're proof positive that durability is embedded in every sheet of metal composing your average shipping container.

As we've seen, not only are these containers built tough with superior materials and crafty design, but with proper care they can outlast most alternatives on the market today by leaps and bounds!

Conclusion: The Importance of Material Choice in Shipping Containers

The material choice in shipping containers isn't a random pick. It's one that carries the weight of careful consideration and detailed engineering. We're talking about those robust, resilient steel boxes that survive the harshest conditions on sea and land, carrying goods halfway across the world.

Consider for a moment what these containers go through. They're loaded onto massive ships, stacked high into the sky, tossed around by stormy seas, then transferred to trucks or trains to finish their journey. That's no easy life!

So why is material choice so important? Well:

- Strength: Can you imagine if these containers were made from anything less hardy than Corten Steel? Not only would they struggle to hold up under severe weather conditions at sea but also while being moved around ports with heavy machinery.

- Security: The tough exterior of Corten Steel is perfect for protecting valuable cargo against theft or damage.

- Longevity: These containers are designed to last! With proper maintenance, they can serve their purpose for 20 years or more.

To illustrate our point further, let's look at some numbers:

| Material | Durability (years) | Strength (MPa) |

| Corten Steel | 20+ | 470 |

| Regular Steel | 10 - 15 | 370 |

As shown above, not only does Corten steel last longer compared to regular steel but it also offers greater strength.

Our discussion on what shipping containers are made of and why it matters, we hope you now understand the significant role materials play in this industry. So next time you see one of these giants crossing international waters or trundling along on a freight train - give a small nod of respect. After all, it's thanks to meticulous engineering and thoughtful selection processes that global trade continues smoothly. And remember, when it comes to choosing a shipping container for your needs, never underestimate the importance of what it's made from!